Ball Mill is one of the fine materials crusher or grinders to nano-size form. It comprises a hollow cylindrical shell or rotating its own axis. It may be the horizontal or vertical direction. It filled the cylindrical shell with balls which are made from chromic steel, rubber, stainless steel and ceramic. An abrasion resistance materials like rubber lining or manganese steel with an inner core-shell (Cylindrical). In the ball, the milling diameter is near ranges to its length in size.

Attrition and Impaction main segmental work. From the upper part of the shell equipment that are helpful for reduction of the bulk material sizes by rotation (either vertical or horizontal).

Working Process

Normally we are using balls to crush the materials, we already discussed the materials in the previous paragraph. Starting from the rotation of the ball mail with its own axis either horizontal or vertical. As it rotates, the ball bounces around while shrinking the enclosed material. The internal force of the strikes helps to grind the material into a finer, and less coarse material. During the rotation with balls, it needs critical speed (the speed at which the enclosed wall rotates along with the inner balls. if balls cannot get speed so it's unlikely to get material to be crushed or there is no impact on the materials.

Measurable points on Ball Mill

1. Ball Mill doesn't have a cutting tool.

2. It differs from Traditional Milling machines (TMM). TMM supports large workpieces while ball mill supports ores, ceramics, paints, etc.

3. During the ball milling process, the collision between tiny rigid balls in the concealed container will generate localized high pressure.

Ball Milling Enzymatic Hydrolysis:

One of the best research papers noted ball milling theory, is that enzymatic hydrolysis performed planetary ball mill machine (DECO-SG 100 from China), aspen was pre-treated 1wt% dilute acid (H2SO4/aspen) for 1 hr across varying temperatures from 150 to 180 degree C). They kept the incubation temperature at 50 degrees Celsius) and the speed was around 800rpm. They conducted the cycle of ball milling enzymatic hydrolysis for 5 min or with 55-minute static incubation. Samples approximately 30 mg each) was collected and analyzed to assess the glucose level.

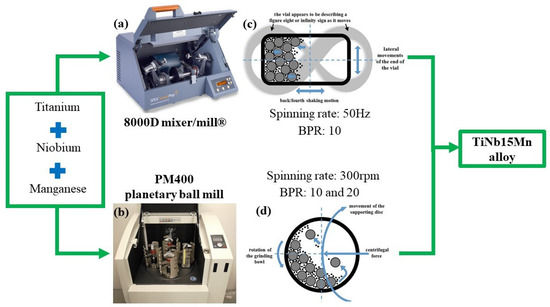

One of the other research investigated in effects of milling parameters on the development of nanostructures alloy with High Energy Ball Milling.

|

–Model |

Dimension(m) |

Volume(m³) |

Ball Load(t) |

Rotation Speed(r/min) |

Power(kw) |

Discharge Size(mm) |

Capacity (t/h) |

Weight(t) |

|

GMQG1530 |

φ1.5×3.0 |

4 |

8 |

27.6 |

75 |

0.074-0.8 |

2.8-12 |

15.5 |

|

GMQG1535 |

φ 1.5×3.5 |

4.6 |

11 |

27.6 |

75-90 |

0.074-0.8 |

3.4-14 |

16.3 |

|

GMQG1830 |

φ 1.8×3.0 |

6.5 |

13 |

25.3 |

132 |

0.074-0.8 |

4.8-21 |

28.2 |

|

GMQG1835 |

φ 1.8×3.5 |

7.58 |

16 |

25.3 |

160 |

0.074-0.8 |

5.8-25 |

30.8 |

|

GMQG1840 |

φ 1.8×4.0 |

8.65 |

17.3 |

25.3 |

185 |

0.074-0.8 |

6.6-28 |

33.4 |

|

GMQG1845 |

φ 1.8×4.5 |

9.75 |

19.5 |

25.3 |

210 |

0.074-0.8 |

7.2-31 |

36.2 |

|

GMQG2122 |

φ 2.1×2.2 |

6.7 |

14.7 |

23.8 |

160 |

0.074-0.8 |

5.3-24 |

43.2 |

|

GMQG2130 |

φ 2.1×3.0 |

9.2 |

17 |

23.8 |

185 |

0.074-0.8 |

6.0-26 |

46.8 |

|

GMQG2136 |

φ 2.1×3.6 |

11 |

19 |

23.8 |

210 |

0.074-0.8 |

6.5-29 |

49.1 |

|

GMQG2140 |

φ 2.1×4.0 |

12.2 |

20.5 |

23.8 |

220 |

0.074-0.8 |

7.2-32 |

50.2 |

|

GMQG2145 |

φ 2.1×4.5 |

13.8 |

22 |

23.8 |

250 |

0.074-0.8 |

8.1-36 |

51.8 |

|

GMQG2424 |

φ 2.4×2.4 |

9.8 |

20 |

22.8 |

220 |

0.074-0.8 |

6.6-32 |

54.8 |

|

GMQG2430 |

φ 2.4×3.0 |

12.2 |

25 |

22.8 |

250 |

0.074-0.8 |

7.5-38 |

57.8 |

|

GMQG2436 |

φ 2.4×3.6 |

14.6 |

30 |

22.8 |

280 |

0.074-0.8 |

8.5-42 |

60.8 |

|

GMQG2440 |

φ 2.4×4.0 |

16.2 |

33 |

22.8 |

355 |

0.074-0.8 |

9.5-47 |

63.8 |

|

GMQG2445 |

φ 2.4×4.5 |

18.2 |

37 |

22.8 |

400 |

0.074-0.8 |

10.5-55 |

66.3 |

|

GMQG2721 |

φ 2.7×2.1 |

10.7 |

24 |

21.7 |

280 |

0.074-3.0 |

8.5-84 |

66.4 |

|

GMQG2727 |

φ 2.7×2.7 |

13.8 |

29 |

21.7 |

315 |

0.074-3.0 |

9.0-105 |

71.7 |

|

GMQG2730 |

φ 2.7×3.0 |

15.3 |

32.5 |

21.7 |

355 |

0.074-3.0 |

10-120 |

77.3 |

|

GMQG2736 |

φ 2.7×3.6 |

18.4 |

39 |

21.7 |

400 |

0.074-3.0 |

12-145 |

82.4 |

|

GMQG2740 |

φ 2.7×4.0 |

20.5 |

43 |

21.7 |

450 |

0.074-3.0 |

13-159 |

84.73 |

|

GMQG2745 |

φ 2.7×4.5 |

23 |

50 |

21.7 |

500 |

0.074-3.0 |

15-180 |

89.1 |

|

GMQG3230 |

φ 3.2×3.0 |

22.65 |

46.9 |

18.6 |

500 |

0.074-3.0 |

16-182 |

139 |

|

GMQG3236 |

φ 3.2×3.6 |

26.2 |

52 |

18.6 |

560 |

0.074-3.0 |

19-190 |

143 |

|

GMQG3240 |

φ 3.2×4.0 |

29.2 |

57 |

18.6 |

630 |

0.074-3.0 |

22-210 |

147 |

|

GMQG3245 |

φ 3.2×4.5 |

32.8 |

65 |

18.6 |

710-800 |

0.074-3.0 |

29-235 |

151 |

|

GMQG3254 |

φ 3.2×5.4 |

39.2 |

81.6 |

18,6 |

800-1000 |

0.074-3.0 |

35-280 |

161 |

|

GMQG3640 |

φ 3.6×4.0 |

35.6 |

75 |

17.3 |

800 |

0.074-3.0 |

25-230 |

185 |

|

GMQG3645 |

φ 3.6×4.5 |

40.8 |

88 |

17.3 |

1000 |

0.074-3.0 |

29-259 |

190 |

|

GMQG3650 |

φ 3.6×5.0 |

45.3 |

96 |

17.3 |

1120 |

0.074-3.0 |

35-288 |

200 |

|

GMQG3660 |

φ 3.6×6.0 |

54.4 |

117 |

17.3 |

1250-1500 |

0.074-3.0 |

38-310 |

220 |

|

GMQG3685 |

φ 3.6×8.5 |

79 |

144 |

17.3 |

1800 |

0.074-3.0 |

50-450 |

260 |